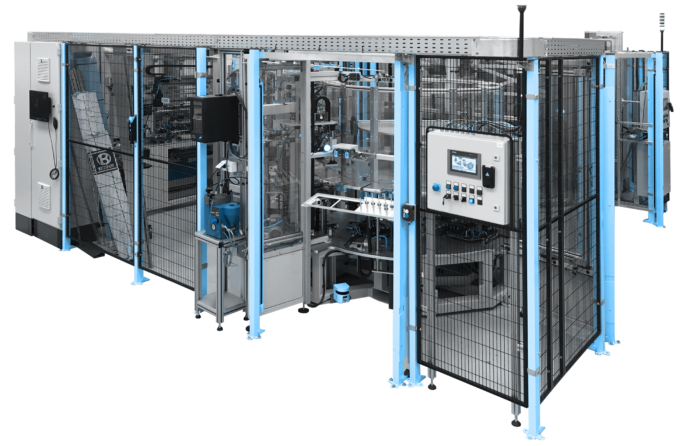

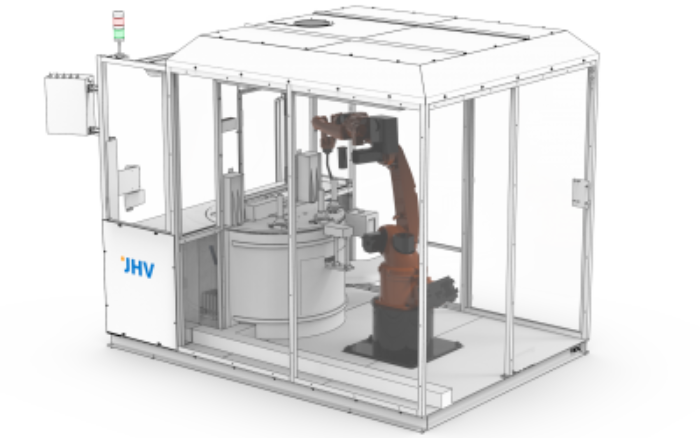

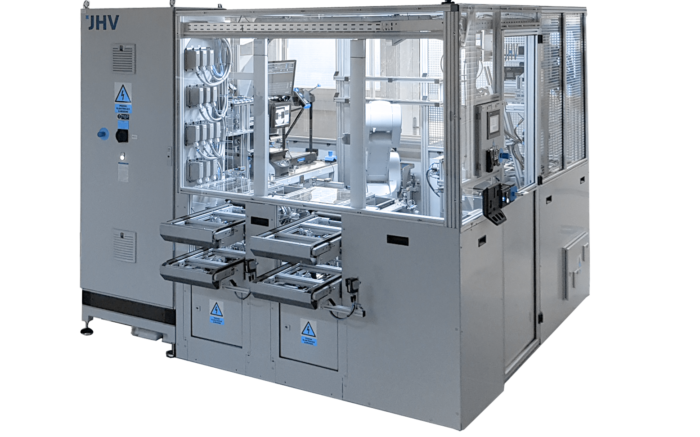

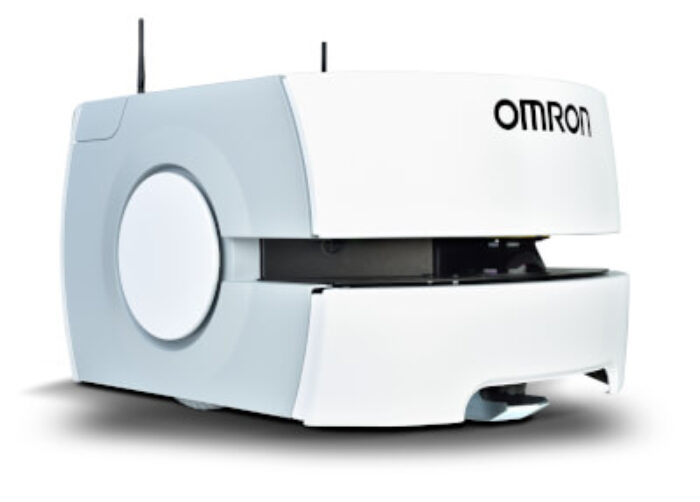

Cooperative robots are ideal as a simple operator replacement in production proces. They will increase the your production efficiency with minimum requirements for editing an existing machine or device. Robots implementation is effective especially for:

- THREE-SHIFT OPERATION

- OPERATOR´S REPLACEMENT

- PRODUCTION INCREASE